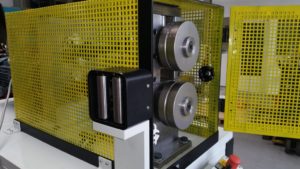

our largest straightening apparatus to date with eccentric —- rolls of 150 mm, made of the highly wear-resistant tool steel 1.2379 – in this case for AL and CU tubes up to 35 mm !!!

RiTeBo GmbH or Andreas Wolff Metalworking from above (Google Earth ) in the industrial area Corunna (Iserlohn,Germany)

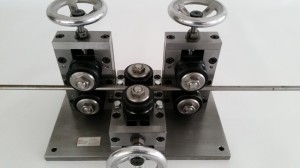

Quatro straightening distance – angle of the individual straightening apparatus is individually adjustable, so that any directional parameter can be achieved

Quadruple driver – reduces slippage during continuous operation – Makes sense if rods or rings are to be cut and this in continuous Operation

Roller guide with an adjustable roller — e.g. for clamping material or precise positioning of the wire

Strip straightening apparatus for directing over the flat side and over the “high” known — here in the picture the straightening mechanism for the “high” kne

Straightening apparatus with position indicators for the adjustable rollers, these are made of PAG 6, the diameter 150mm with round profile

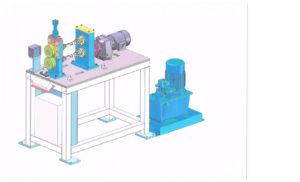

Propulsion device with hydraulic unit, completely ready for connection, including control electronics

3D view propellant VT 150 complete with unit and electric – protective hood according to UVV has been removed for display

Straightening apparatus with eccentric quick opening, the adjustable straightening rollers with mechanical position indicators

Side view shell construction propellant VT 150 – including hydraulic unit – “ready to connect” protective hood according to UVV is still missing

Wire 2016 -Everyone meets at RiTeBo—. Company.Kraus in friendly conversation with Mr. Terbeck from Ernst Koch-Ihmert

Simple role adjustment, 2 keys are needed to “counter”, roll does not move back automatically, easy adjustment

In a spindle adjustment, the roll moves forwards and backwards when turning the waistnut – self-locking fuse, modern spindle adjustment

![]()